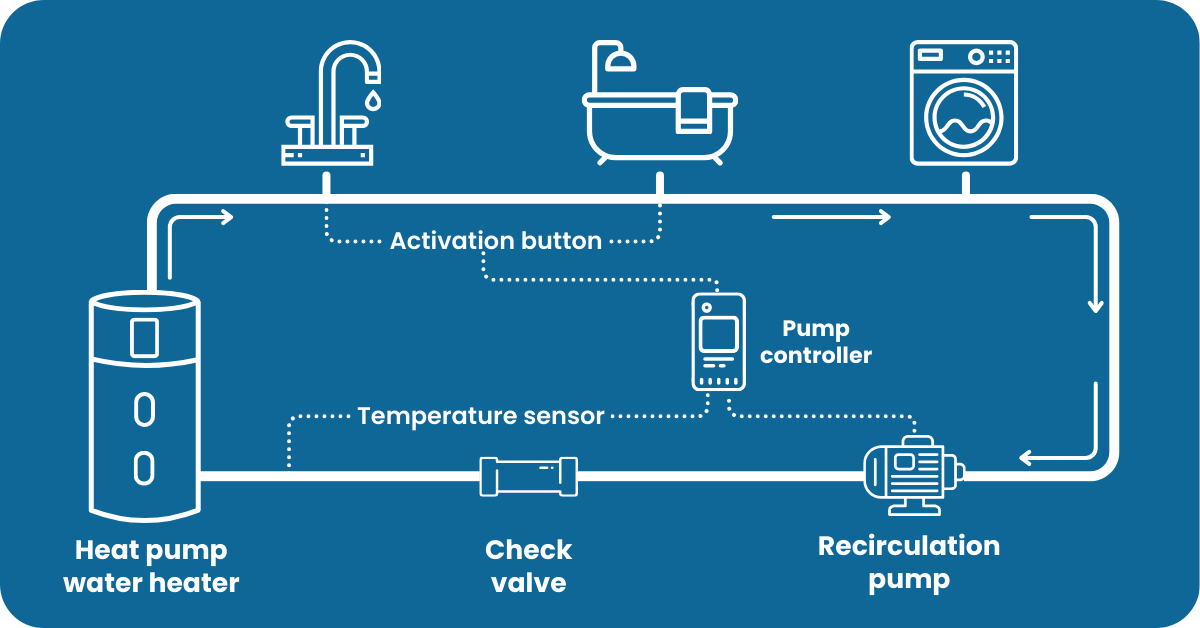

A recirculating pump is an inline pump installed as part of a home’s water heating system to circulate hot water between the water heater and the various faucets and showers (fixtures) throughout the residence. When installed correctly, a recirculation pump can save water by reducing the time-to-tap for hot water delivery—resulting in less cold water down the drain.

Heat pump water heaters (HPWH) do not require a recirculation pump to operate. It is the water heating system and the customer’s preferences on whether a recirculation system is right for them.

When a HPWH is installed in an existing home in a retrofit, that water heating system may already have a recirculation loop and pump. In new construction, the designer may choose to build a recirculation loop, or locate the water heater near fixtures to obviate the need for a recirculation pump. In either scenario, special considerations are needed to ensure the recirculation pump does not negatively impact the HPWHs ability to produce hot water efficiently.

HPWHs rely on temperature stratification across their storage tanks. This provides a buffer of hot water at the top of the tank that is ready for use and reduces the units need to provide on-demand heating. Cold water enters at the base of the tank and is heated as needed and in a manner that yields the lowest energy consumption by the heat pump to replenish the buffer. To lock in this highly efficient heating approach, many HPWHs are programmed to detect a large temperature drop in the base of the tank before activating the heat pump.

Hot water in a recirculation loop loses heat as it flows out from the water heater, past the fixtures, and back to the tank. In a continuous or highly active recirculating loop, this frequent addition of warm water to the tank will result in an unstratified tank of lukewarm water. Because of this, all major manufacturers of unitary HPWHs state that if a recirculation system is installed with a HPWH, the recirculation pump must be demand-controlled. Otherwise, the majority of the heating will come from inefficient electrical resistance.

Demand-controlled recirculation is the solution. If the recirculation pump can anticipate or be primed just before hot water is needed, users can reduce their water consumption while preserving the energy savings of their HPWH. Demand controls can cut pump run time to just minutes per day by activating only with user input or sensors just before hot water is needed. The table below outlines a few of the demand control options for recirculation pumps.

A physical switch to activate recirculation.

Pros: Switch located at point of use

Cons: Additional hardware to install, requires user knowledge

A wireless switch, e.g., Bluetooth connected, to activate recirculation.

Pros: Less hardware to install

Cons: Requires batteries (maintenance); Requires user knowledge/access

Detects user presence before hot water is needed.

Pros: Doesn't require user awareness

Cons: Additional hardware to install; False positives lead to unnecessary pump activations and energy use

Recirculation pumps are only one aspect of a well-designed recirculation system. Loop design, water heater and fixture placements, pipe sizing, pipe location, insulation, and flow rates are all critical pieces of a system.

Always follow applicable building codes and manufacturer installation instructions for both the HPWH and additional equipment, such as a recirculation pump.

Check out these resources on design considerations for recirculation systems.

Best Practices for Retrofit Installations

RHA’s Best Practices for the Retrofit Installation of Heat Pump Water Heaters. See Appendix 7 on page 25 for information on controller recirculation pumps.

Best Practices for New Construction

EPA’s WaterSense® Guide for Efficient Hot Water Delivery Systems